No products in the cart.

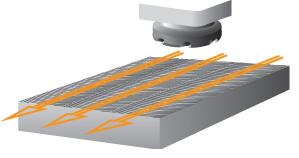

When cutting a large plate with a smaller diameter cutter, it requires multi-pass cutting, and when the cutting-pass is increased, the machining time becomes even longer. Also, the multi-pass cutting can leave ridges between the cutting tracks, which requires highly skilled programmers to run the machine.

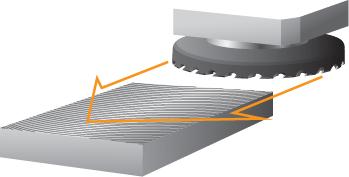

This machine is equipped with a large 20.669″ (525 mm) diameter cutter, which enables the one-pass cutting of up to 19.685″ (500 mm) in width, eliminating the ridges that are made with cutting with the smaller diameter cutter.

| Model | PMH1308 | ||

|---|---|---|---|

| Body | Index Table Size | 55.1″ x 26″ | 1400 x 660 mm |

| Max Longitudinal Travel (X-Axis) | 62.2″ | 1580 mm | |

| Max Cross Travel (Y-Axis) | 22.0″ | 560 mm | |

| Max Vertical Travel (Z-Axis) | 16.1″ | 410 mm | |

| Distance from Insert Edge to Table Surface | 1.57″ – 17.71″ Cutter Thickness: 3.94″ | 40 – 450 mm Cutter Thickness: 100 mm | |

| Distance from Spindle Center to Column | 23.2″ | 590 mm | |

| Capacity | Max Material Dimensions (W x L x H) | 51.1″ x 31.5″ x 11.8″ | 1300 x 800 x 300 mm |

| Face Mill Cutter Diameter | Dia. 20.7″ | Dia. 525 mm | |

| Table Loading Capacity (Workpiece + Magnetic Chuck) | 7716 lb | 3500 kg | |

| Feed Speed | Rapid Feed Speed (X & Y-Axis) | 65.6 ft/min | 20 m/min |

| Rapid Feed Speed (Z-Axis) | 49.2 ft/min | 15 m/min | |

| Cutting Feed Speed | 0.039 – 78.74 in/min | 1 – 2000 mm/min | |

| Spindle | Spindle Diameter | Equivalent to JIS No.60 | |

| Spindle Nose | dia. 1.875″ pilot boss | dia. 47.625 mm pilot boss | |

| Spindle Speed | 60 – 250 rpm | ||

| Spindle Speed (Optional High-Speed Spec.) | 60 – 400 rpm | ||

| Max Spindle Torque | 1660 Nm | ||

Motors | Spindle Motor (AC Spindle, 50% ED/cont.) | 30/25 HP | 22/18.5 kW |

| Feed Motor (X & Y-Axis) (AC Servo Motor) | 4 HP | 3 kW | |

| Feed Motor (Z-Axis) (AC Servo Motor) | 4 HP | 3 kW | |

| Spindle Lubricant Pump | 0.1 HP | 0.075 kW | |

| Spindle Surface Lubricant pump | 0.007 HP | 0.005 kW | |

| Machine Dimensions (W x L x H) (without safety fence) | 155.9″ x 131.9″ x 112.2″ | 3960 x 3550 x 2850 mm | |

| Machine Weight | 24250 lb | 11000 kg | |

| Spindle Lubrication Oil Tank | 2.9 gal. | 11 liter | |

| Spindle Surface Lubricant Oil Tank | 0.48 gal. | 1.8 liter | |

| Cutter Heeling | 0.0012″/11.8″ | 0.03/300 mm | |

| Air Pressure Requirement | 71.25psi and over, 105.67 gal./min and over | 0.5Mpa and over, 400L/min and over | |

| Electric Power Requirement | 35 kVA, AC200/220V ±10%, 50/60Hz | ||

Specifications and the machine design may change without notice at the sole discretion of Amada’s Engineering Department.

Contact for repairand recovery of AMADA products and our corporate activities.

©2021 Amada Machinery America Inc. All Rights Reserved. Website Design and Development by Stellar Blue Technologies.