No products in the cart.

Amada Machine Tools America Inc., in association with North American Steel Alliance would like to share with you some information that may be benificial to your operations.

Amada is well aware of the difficulties Steel Service centers are faced with in this highly competitive market. We know you need to pre-process and cut materials in the most efficient way possible to maintain profit levels.

Here are two products that many other Steel Service Centers find efficient.

DYNASAW 430/530 High Peformance CNC Band Saw

Double Vibration Dampening Rollers

Double rollers reduce vibration resulting in faster and quieter cutting while improving blade life.

New Saw Blade Frame Design

Longer blade life by reducing the twist in the blade, fatigue is greatly reduced leading to longer blade life.

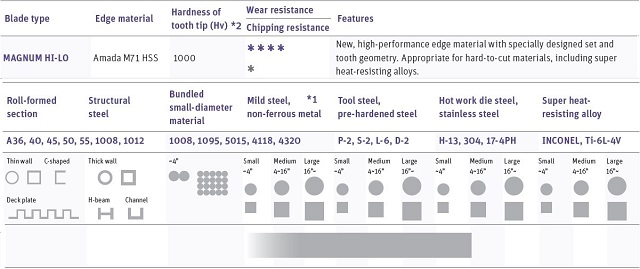

MAGNUM Hi-Lo

Patented Varying Tooth Height and Set M-71 Blade for Metal Cutting Band Saws. Superior Performance for Cutting Work Hardening Tools Steels and Other Tough to Cut Metals.

With its special alloying technology, Magnum Hi Lo achieves HRC70 tooth hardness. It maintains positive cutting action and outlasts other blades in production cutting of large-diameter, work hardening steels and nickel-base super alloys with tensile strength of up to 164,000 psi.

Machine Quote for Saws and Milling (847)-285-4800 ext 606

Specifications may change without notice at the sole discretion of Amada’s Engineering Department.

©2021 Amada Machinery America Inc. All Rights Reserved. Website Design and Development by Stellar Blue Technologies.