Subtotal:

| Model | THV460 | ||

|---|---|---|---|

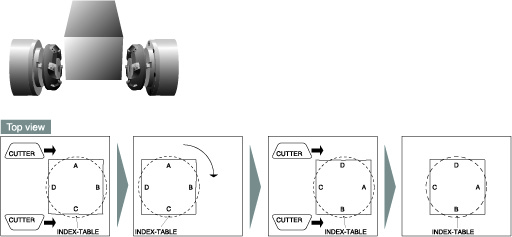

| Body | Index Table Size | Diameter 13.7″ | Diameter 350 mm |

| Max Longitudinal Travel (X-axis) | 24.0″ | 610 mm | |

| Max Cross Travel (Y&X-axis) | 12.5″ | 320 mm | |

| Distance from Spindle Nose to Table Center | 2.87″-15.47″ | 73-393 mm | |

| Distance Between Both Spindle Nose | 5.75″ – 30.94″ | 146 – 786 mm | |

| Distance from Table Surface to Spindle Center | 4.33″ | 110 mm | |

| Index Table Driving Angle | 0/45/90/135 Degree | 0/45/90/135 Degree | |

| Capacity | Max Material Dimensions (W x L x H) | 18.4″ x 18.4″ x 5.9″ | 468 x 468 x 150 mm |

| Max Machining Dimensions (W x L x H) | 18.4″ x 18.4″ x 5.9″ | 468 x 468 x 150 mm | |

| Min Machining Dimensions (W x L x H) | 0.787″ x 0.787″ x 0.394″ | 20 x 20 x 10 mm | |

| Chamfering Size | Max C3 | ||

| Face Mill Cutter Diameter | Diameter 6.3″ | Diameter 160 mm | |

| Table Loading Capacity (Max Workpiece Weight) | 705 lbs | 320 kg | |

| Feed Speed |

Rapid Feed Speed (X-Axis) | 65.6 ft/min | 20 m/min |

| Rapid Feed Speed (Y & Z-Axis) | 32.8 ft/min | 10 m/min | |

| Cutting Feed Speed (Manual) | 0.039-59.05 in/min | 1-1500 mm/min | |

| Cutting Feed Speed (Auto) | 0.039-196.85 in/min | 1-5000 mm/min | |

| Handle Feed (Manual Pulse Generator) | 0.000039/0.00039/0.0039″/1pulse | 0.001/0.01/0.1 mm/1 pulse | |

| Spindle | Spindle Diameter | Equivalent to JIS No.50 | |

| Shape of Spindle Nose | Dia. 2″ Pilot Boss (HSK-A100 Taper Hole) | Dia. 50 mm Pilot Boss (HSK-A100 Taper Hole) | |

| Spindle Speed | 100-1000 RPM | ||

| Spindle Speed (Optional High-Speed Spec.) | 100-2000 RPM | ||

| Max Spindle Torque | 307 Nm | ||

|

Motors |

Spindle Motor (AC Servo Motor) | 20/15 HP x 2 | 15/11 kW x 2 |

| Feed Motor (X-Axis) (AC Servo Motor) | 3 HP | 2.0 kW | |

| Feed Motor (Y & Z-Axis) (AC Servo Motor) | 2 HP x 2 | 1.5 kW x 2 | |

| A-Axis (AC Servo Motor) | 1.5 HP | 1.0 kW | |

| Hydraulic Unit | 3 HP | 2.2 kW | |

| Chip Conveyor | 1/4 HP | 0.2 kW | |

| Lubrication Oil Pump | 1/40 HP | 0.018 kW | |

| Machine Dimensions (W x L x H) | 126.0″ x 126.7″ x 85.9″ | 3200 x 3219 x 2181 mm | |

| Machine Weight | 17,637 lbs | 8,000 kg | |

| Hydraulic Oil Tank | 5.28 gal | 20 liters | |

| Lubrication Oil Tank | 0.48 gal | 1.8 liters | |

| Cutter Heeling | 0.0012″/11.8″ | 0.03/300 mm | |

| Air Pressure Requirement | 71.25 psi and over, 79.25 gal/min and over | 0.5 Mpa and over, 300L/min and over | |

| Electric Power Requirement | 44 kVA, AC200/220V±10%, 50/60Hz | ||

Specifications and the machine design may change without notice at the sole discretion of Amada’s Engineering Department.

Contact for repairand recovery of AMADA products and our corporate activities.

©2021 Amada Machinery America Inc. All Rights Reserved. Website Design and Development by Stellar Blue Technologies.