Subtotal:

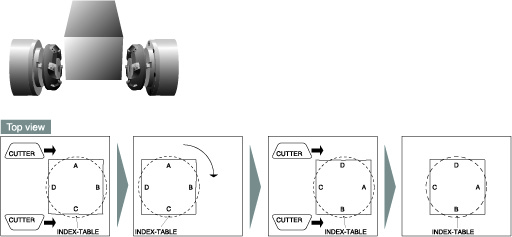

This means the twin spindle milling machine enables automatic milling of four surfaces with on one setting, reducing setting time, increasing efficiency and reducing running cost.

| Model | THV150 | ||

|---|---|---|---|

| Body | Index Table Size | Dia. 7.87″ | Dia. 200 mm |

| Max Longitudinal Travel (X-axis) | 11.8″ | 300 mm | |

| Max Cross Travel (Y&X-axis) | 4.84″ | 123 mm | |

| Distance from Spindle Nose to Table Center | 1.57″ – 6.41″ | 40 – 163 mm | |

| Max Distance Between Both Spindle Nose | 9.68″ | 246 mm | |

| Index Table Driving Angle | 0/45/90/135 Degree | 0/45/90/135 Degree | |

| Capacity | Max Material Dimensions (W x L x H) | 6.3″ x 6.3″ x 5.9″ | 160 x 160 x 52 mm |

| Max Machining Dimensions (W x L x H) | 5.9″ x 5.9″ x 2.05″ | 150 x 150 x 52 mm | |

| Min Machining Dimensions (W x L x H) | 0.276″ x 0.276″ x 0.276″ | 7 x 7 x 7 mm | |

| Chamfering Size | Max. C2 | ||

| Face Mill Cutter Diameter | Dia. 2.48″ x thickness 1.57″ | Dia. 63 mm x thickness 40 mm | |

| Table Loading Capacity (Max Workpiece Weight) |

44.1 lb. | 20 kg. | |

| Feed Speed |

Rapid Feed Speed (X-Axis) | 32.8 ft/min | 10 m/min |

| Rapid Feed Speed (Y & Z-Axis) | 26.2 ft/min | 8 m/min | |

| Cutting Feed Speed (Manual) | 0.039 – 59.05 in/min | 1 – 1500 mm/min | |

| Cutting Feed Speed (Auto) | 0.039 – 196.85 in/min | 1 – 5000 mm/min | |

| Handle Feed (Manual Pulse Generator) | 0.000039/0.00039/0.0039 in/1 pulse | 0.000039/0.00039/0.0039 in/1 pulse | |

| Spindle | Spindle Diameter | Equivalent to JIS No.30 | |

| Spindle Nose | Dia. 0.866″ | Dia. 22 mm | |

| Max Spindle Speed | 4500 RPM | ||

| Spindle Speed (Optional High-Speed Spec.) | 8000 RPM | ||

| Max Spindle Torque | 35 Nm | ||

|

Motors |

Spindle Motor | 5/7.5 HP x 2 | 3.7/5.5 kW x 2 |

| Feed Motor (X-Axis) | 1 HP | 0.75 kW | |

| Feed Motor (Y & Z-Axis) | 3/4 HP x 2 | 0.5 kW x 2 | |

| A-Axis Index Table Motor | 3/4 HP | 0.5 kW | |

| Clamper | 3/4 HP | 0.5 kW | |

| Positioning System | 3/40 HP | 0.05 kW | |

| Machine Dimensions (W x L x H) | 59.1″ x 59.1″ x79.6″ | 1500 x 1500 x 2023 mm | |

| Machine Weight | 4409 lb | 2000 kg | |

| Cutter Heeling | 0.0012″/11.8″ | 0.02/50 mm | |

| Air Pressure Requirement | 71.25 PSI and over, 79.25 gal/min and over | 0.5 Mpa and over, 300 L/min and over | |

| Electric Power Requirement | 16 kVA, AC200/220V ±10%, 50/60Hz | ||

Specifications and the machine design may change without notice at the sole discretion of Amada’s Engineering Department.

Contact for repairand recovery of AMADA products and our corporate activities.

©2021 Amada Machinery America Inc. All Rights Reserved. Website Design and Development by Stellar Blue Technologies.